Thermal Insulation beneath Underfloor Heating

Why conventional underfloor heating systems have an insulation layer and low profile underfloor heating generally does not

The classic underfloor heating system, with a heating screed over the heating pipes, usually also has thermal insulation. Why is this?

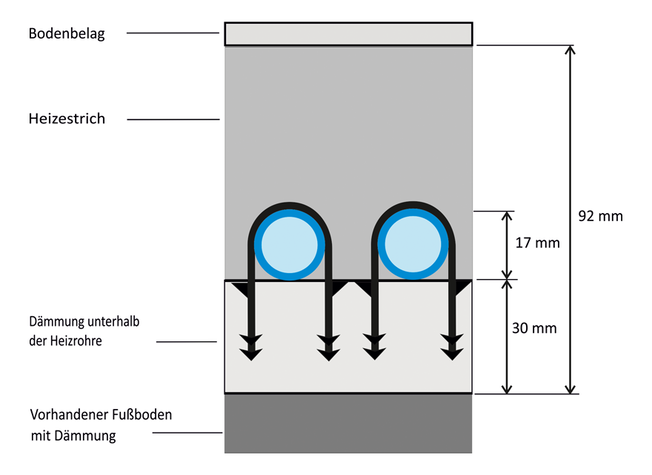

The thickness of the heating screed and the insulation under the heating pipes are interdependent. The 50 mm thick screed protects the insulation from being crushed by traffic loads. The screed creates a thermal resistance above the heating pipes that prevents efficient heat transfer to the room. The insulation under the heating pipes must therefore ensure that the heat does not escape into the floor structure before it can reach the floor surface and work its way into the room.

The thick layer of heated screed also acts as a heat accumulator. What sounds good in theory often has disadvantages in practice. When not much heat is needed in the room, this 'heat store' heats up. When the underfloor heating is switched on after a period of inactivity, the heated screed extends the heating time and delays the release of heat into the room. The response time of the underfloor heating slows down.

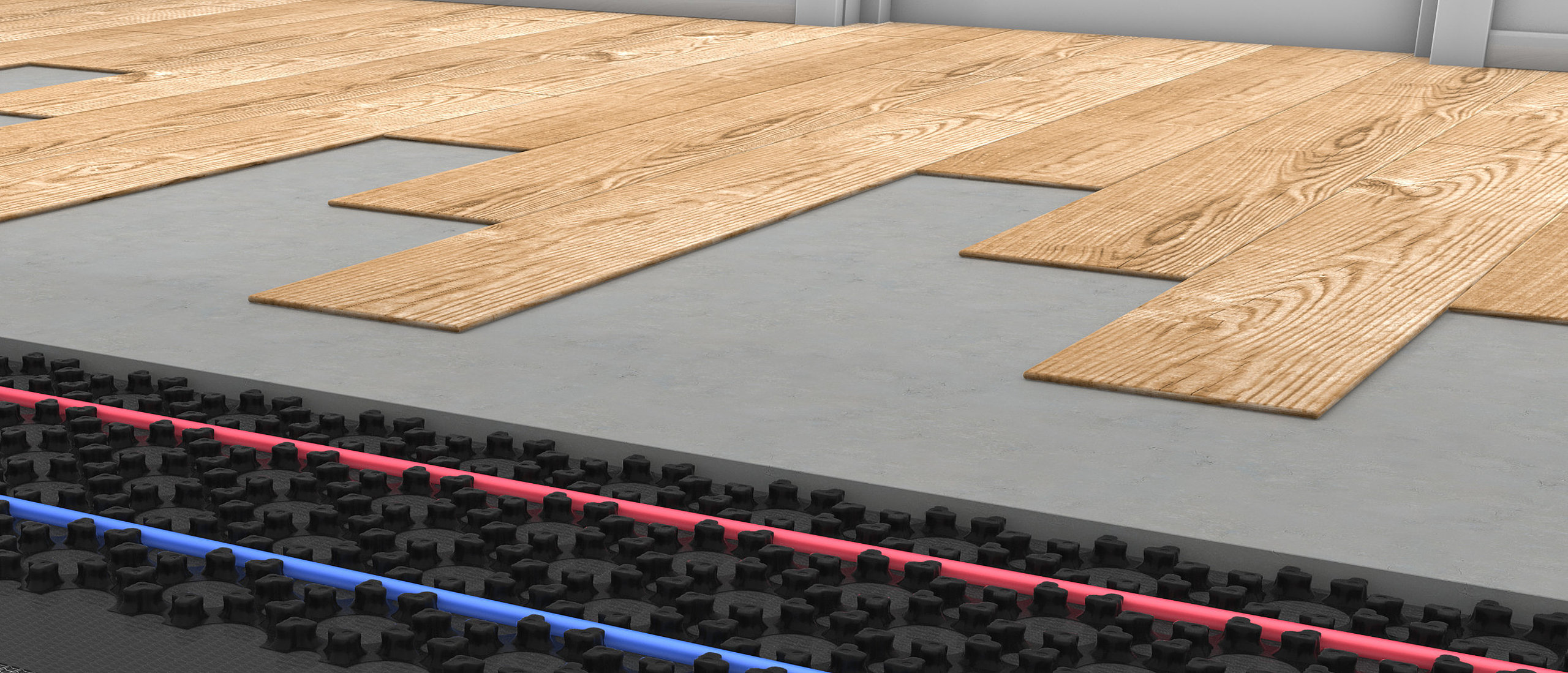

This is another disadvantage of conventional underfloor heating systems: Insulation and screed usually have a construction height of 65 to 90 mm. This construction places a significant additional load of approximately 110 kg/m2 on the existing ceiling. This approach is often unsuitable for retrofitting underfloor heating in existing and older buildings.

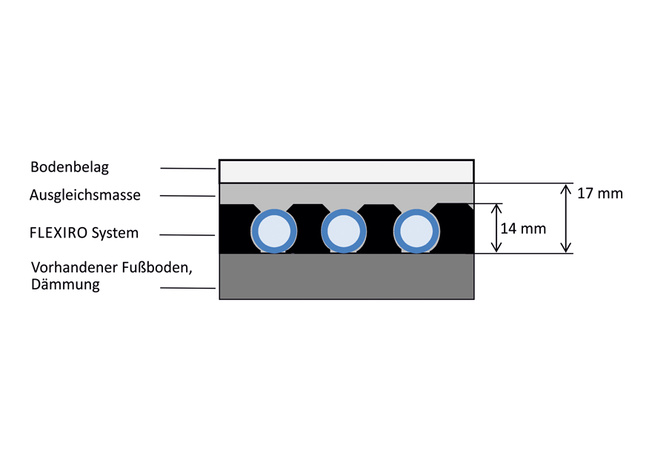

From a thermal point of view, the insulation of a floor slab is negligible as long as the rooms above and below the slab are heated. It is only for sound insulation that insulation measures are required. FLEXIRO thin layer underfloor heating makes use of these insulation layers. When FLEXIRO low profile underfloor heating is installed on an existing floor, the "thermal resistance" of all the materials installed in the ceiling acts as sufficient insulation downwards. The thin heating pipes lie just below the floor surface and therefore transfer heat into the room quickly and with almost no loss.

In addition, the heating water temperatures of the thin-bed underfloor heating system, at around 35°C, are much closer to the desired room temperature than the temperatures of conventional underfloor heating, which are around 45°C for a comparable heat output. This is another reason why the 'heat loss' to the floor structure is significantly lower with thin layer underfloor heating. For these reasons, there is generally no need for additional insulation beneath the underfloor heating system.

Minimum thermal resistance of the insulation layer

The current German Energy Saving Ordinance (EnEV) provides information on the insulation requirements and minimum values for the thermal insulation of the upper storey ceiling and the lower storey ceiling above the basement or ground. DIN EN 1264-4 for surface-integrated heating and cooling systems with water flow, together with the Energy Saving Ordinance, regulates compliance with insulation values for underfloor heating systems. Existing insulation in floors or suspended ceilings below can be included in the calculation of the insulation values. Below are the thermal resistance specifications for different room conditions.

|

Heated room underneath |

Unheated or intermittently heated room below or room lying directly on the ground |

Room below with outside air temperature |

||

External design temperature Td >=0°C |

External design temperature 0°C<Td >=-5°C |

External design temperature -5°C>Td >=-15°C |

|||

Thermal resistance (m2K)/W |

0.75 |

1.25 |

1.25 |

1.50 |

2.00 |

Table from DIN EN 1264-4

If the thermal resistance of the insulation is insufficient

In a modernisation project, it is sometimes the case that the existing floor structure does not provide the minimum thermal insulation required for the energy-saving operation of the underfloor heating system. This can be the case when converting an old barn into a house, or when modernising a room above an unheated cellar or passageway. As it is not pleasant to stand on a cold floor, even in summer, you should consider a complete overhaul of the floor structure.

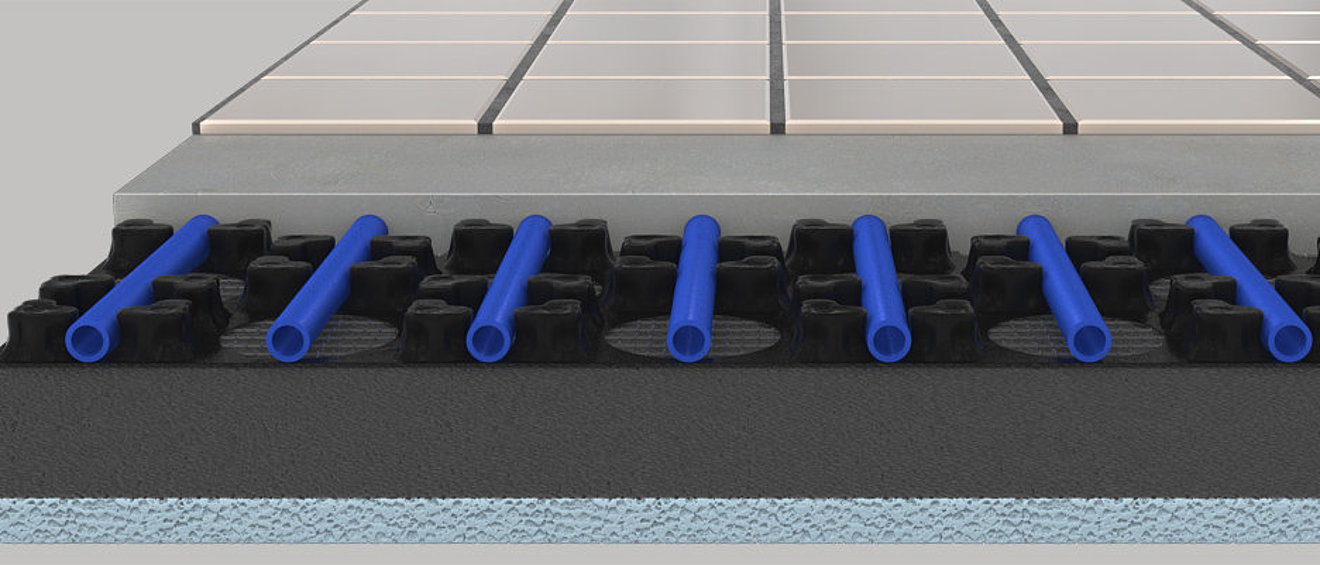

The insulation of the thin layer underfloor heating can be achieved by doubling it. FLEXIRO offers structural insulation boards in various thicknesses for this purpose. The insulation boards are glued to the prepared old floor. The technical description of the installation of the insulation boards gives precise instructions on how to proceed. The FLEXIRO underfloor heating can be installed on the rigid insulation boards using the dimpled board installation method. After pouring a self-levelling compound over the 10 mm PE-RT heating pipes, the floor structure can be finished with tiles, laminate or vinyl.

This levelling method can also be used to compensate for height differences between rooms. If the uninsulated area is a cellar ceiling and the cellar is not heated, the insulation boards can also be installed on the ceiling from the cellar.