Retrofitting Underfloor Heating in Old Buildings

Living in an old building but with modern heating

"Proper heating" or "best heating" are among the trending topics of recent years. This subjective impression is confirmed by a look at Google Trends. It should be comfortable, but energy efficient and environmentally friendly. The trend for heat sources in new buildings is towards heat pumps. In terms of heat distribution systems, underfloor heating is leading the way, as its low flow temperatures make it particularly compatible with heat pumps. The German Association for Surface Heating and Cooling estimates that 80-90% of new detached and semi-detached houses will have underfloor heating. The lion's share of these will be water-bearing underfloor heating systems.

The challenge of energy modernisation in existing buildings

In 2022, 49% of homes were still heated with gas and 25% with oil. The heat pump has a share of 3%.

The high investment costs of upgrading the entire heating system, the lack of thermal insulation and the limited possibility of using the flats while the work is being carried out prevent many owners from converting the heating system to underfloor heating. From an environmental point of view, this means that the "heating turnaround in existing buildings" falls far short of the targets set by the German government for the building sector in order to achieve the climate targets. From the point of view of the owner or tenant, this means an unnecessary sacrifice of modern heating comfort.

Does it make sense to retrofit underfloor heating without replacing the heat source?

How can the comfort of underfloor heating be retrofitted in existing and old buildings if investing in a new heat source is not an option? The FLEXIRO solution allows the gradual introduction of underfloor heating in existing buildings. The heating kits can be installed in rooms where thermal comfort is particularly important. There is no need to replace the heating source. It can also be connected to heating systems with high flow temperatures via return temperature limiters.

Retrofitted underfloor heating can either replace existing radiators or be used in addition to radiators where thermal insulation is poor. In this way, the thermal comfort of underfloor heating can be retrofitted in a targeted manner and the modernisation of the heating source can be prepared by gradually introducing panel heating.

info

Calculation of the heating surface

Depending on the room conditions and heating requirements, a heating surface of 60 to 85% of the room area should be planned for underfloor heating.

Kitchen units or other storage areas should be left out during installation. For example, 10 m² of underfloor heating can provide sufficient heat for rooms between 12 and 16 m².

What makes low profile underfloor heating so attractive

The minimum installation height of FLEXIRO underfloor heating is 17 mm. The low height of the underfloor heating means that it can be installed on top of the existing floor. Whether directly on a floor board or on an existing screed, this option minimises the work involved. In some old buildings, this is the height of the door threshold. A high quality parquet floor can then be laid over the underfloor heating.

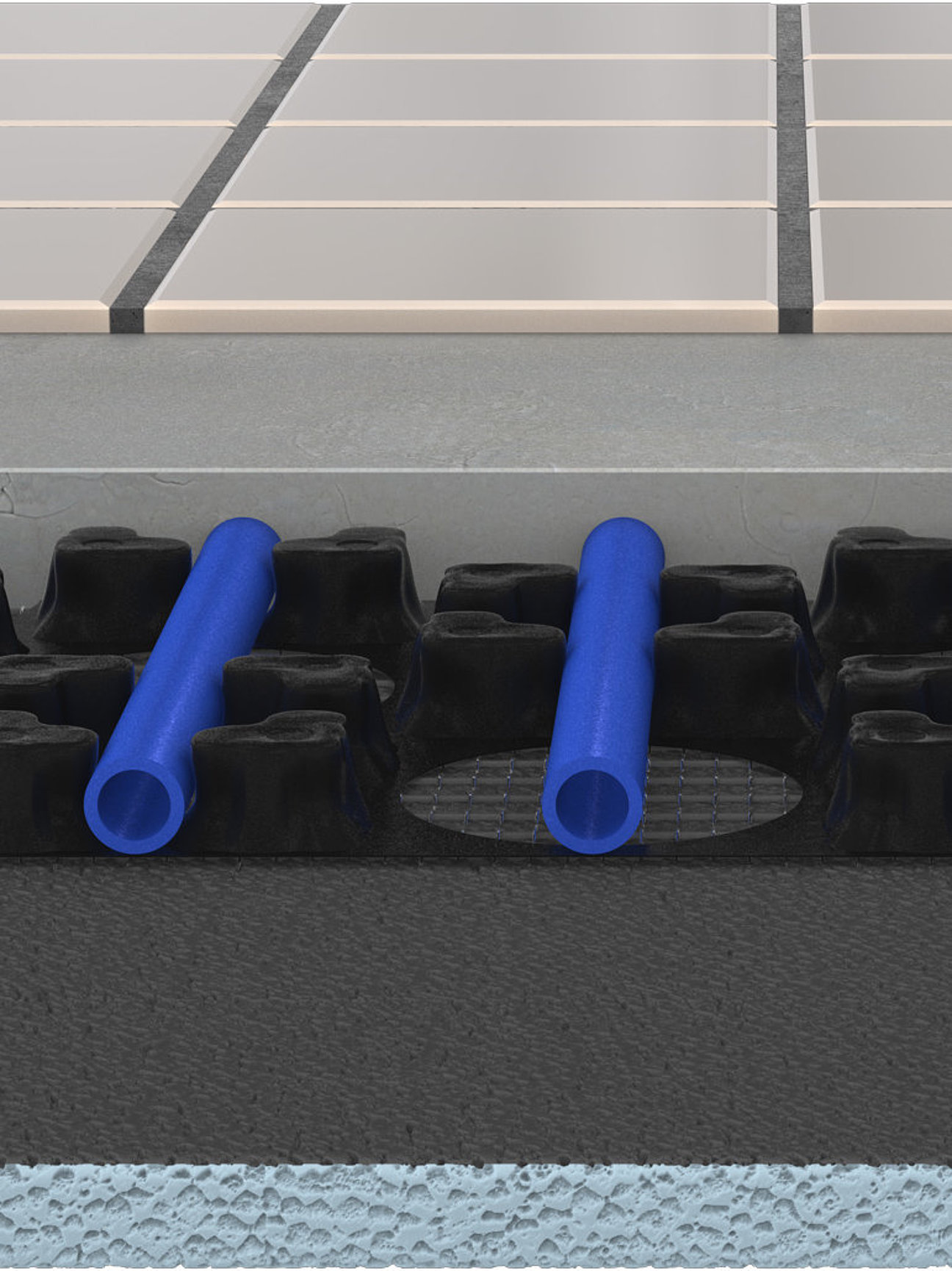

Laying the 10 mm thin heating pipe in tight loops directly under the floor surface also provides excellent heating values and rapid heating up of the underfloor heating. The effect of the radiant heat is fully utilised thanks to the even heating of the floor.

Drywall, clip rail or studded plates?

Drywall

add_circle

Dry construction is fast, clean and introduces little moisture into the room. As a result, follow-up work can be completed quickly and the space returned to use.

highlight_keyboard_focus

The dry screed boards are relatively heavy and potentially fragile. Two people are required to install them. The manufacturer Fermacell recommends a three-layer structure.

Clip rail

add_circle

Mounting with clip rails is particularly recommended for mounting on uneven floors such as wooden floors. It is also the least expensive of the three options.

highlight_keyboard_focus

The loops of the heating pipes may also need to be secured to the floor with dowel hooks. Otherwise the pipes could float, requiring additional grouting. This increases the cost and height of the installation.

Studded plate

add_circle

If the subfloor is smooth, the heating pipes can be fixed to the floor with stud plates. This minimises the amount of levelling compound required. This saves costs and reduces the reaction time of the underfloor heating.

highlight_keyboard_focus

The existing floor must meet the requirements for full-surface adhesion of the studded plates. Unevenness and residual moisture will affect the adhesion of the panels.

Underfloor heating systems

forum

The Bostik company says yes! However, floating timber structures are not permitted as they are highly susceptible to deformation. Installation is therefore only possible on fixed timber structures, whereby these must be uncoupled. Please contact us for further information on laying on fixed timber structures!

The existing substrate must always be level, clean, dry and load-bearing.

FLEXIRO underfloor heating can be installed on OSB boards. Bostik's instructions clearly state that the OSB boards must be bonded to the substrate. Floating OSB boards are not suitable. The OSB boards must be primed before laying the FLEXIRO underfloor heating. In this case, the pipes should be covered with at least 5 mm of screed.

Due to the installation of the low profile underfloor heating directly below the surface, additional insulation is not required in most cases. This keeps the installation height low. Exceptions are floors above unheated basements and the ground. The requirements of the Energy Saving Ordinance must be observed. Further information on thermal insulation for underfloor heating

The low profile underfloor heating is designed for mounting directly on the existing surface. The modernisation of an existing and already insulated floor usually does not require additional insulation of the underfloor heating. Therefore we only sell special insulation boards for bathrooms and other wet areas. Additional floor insulation can be bought at any specialist store. Once the insulation has been applied, you need to ensure a stable surface before installing the underfloor heating.