Turning the Ceiling Heating into a Cooling Ceiling

Retrofitting a chilled ceiling - enjoy the summer at home

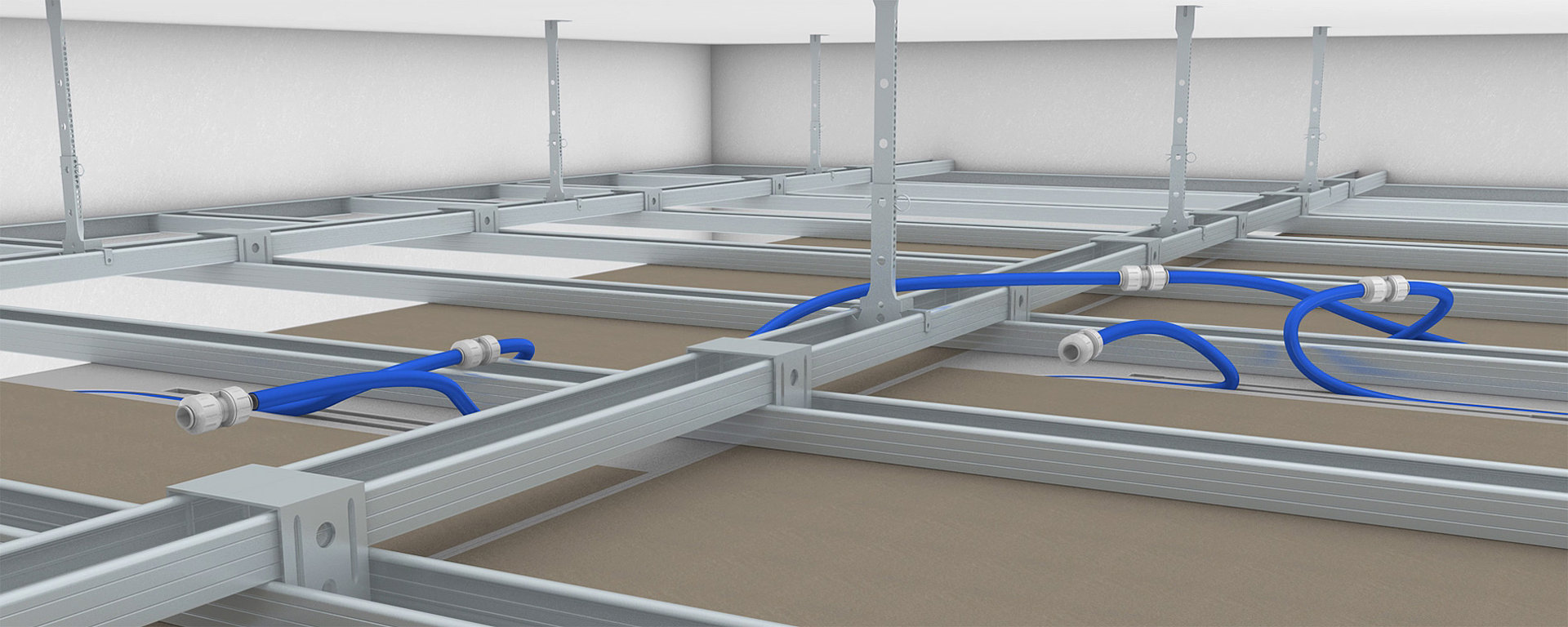

The FLEXIRO drywall ceiling heating system can also be used for energy-efficient and quiet cooling in summer. By supplying the system with cooling water, the ceiling heating can also be used to retrofit a chilled ceiling. Heat is absorbed by the cooled ceiling and removed by circulating cooling water. The result: the room cools down evenly in a comfortable and healthy way. Heat is transported upwards by radiant heat from surfaces and people in the room, as well as by the warm air in the room, which rises to the ceiling, cools down and then falls back down again, cooled. The ceiling cooling effect is achieved through the surface. The position of the 10 mm PE-RT pipes close to the surface, integrated into the drywall elements, increases the efficiency. The disruptive effects of air conditioning, such as cold draughts and noise, are avoided.

The main challenge when using a ceiling heating system as a chilled ceiling is to ensure a sufficient supply of cooling water over a long period of time. Approximately 10 litres of chilled water at a temperature of 17-18°C per square metre of active area must be pumped through the ceiling system every hour.

Where does the cooling water come from?

The need for cooling water limits the applications of a chilled ceiling. What sources are suitable for operating a chilled ceiling?

Solution 1 Passive heat pump

The use of heat pumps is a convenient and cost-effective technology. Where a geothermal heat pump can be used, the required cooling water can be provided by passive cooling alone. The lower temperature in the ground is sufficient to cool the water temperature sufficiently for the cooling ceiling via a plate heat exchanger. Passive cooling eliminates the need for a heat pump compressor. This keeps electricity consumption low. Disadvantage: The ground can only absorb a limited amount of recirculated heat. In long, hot summers, the cooling capacity of the ceiling can therefore decrease.

Solution 2 Reversible heat pump

The ceiling can be actively cooled using a reversible heat pump, with a choice of brine-to-water or air-to-water pumps. The reversible heat pump works as a cooling unit in summer and as a heating unit in winter. This technology provides reliable cooling even during high summer temperatures.

Solution 3 Split cooling technology

If the existing heating system is not to be changed, split chiller technology is a good option for supplying chilled water. With this technology, the evaporator and condenser are separate. This means that the low-noise, air-cooled condenser can easily be installed outside, while the evaporator can also be installed inside the building.

Solution 4 Utilisation of natural temperature sinks

If a natural source such as well water, cistern water or flowing or stagnant open water is considered for cooling, it must first be verified that the energy content of this source is sufficient to supply the chilled ceiling with cold for several hours a day. It must also be ensured that the natural cold source has sufficient time to regenerate the temperature during the operating time of the chilled ceiling. The return of water with increased temperatures to the natural environment must not cause any damage. Official approval may be required for the return of heat.

What needs to be considered when operating the cooling ceiling?

Every chilled ceiling needs to be protected against the condensation of humidity on the ceiling. A reliable way of preventing this is to ensure that the supply temperature of the chilled water is always slightly higher than the dew point temperature at which moisture starts to condense. To find out what the normal dew point temperature is in your area, check with the Met Office. A rule of thumb for Central European climates is that the cooling water temperature must be at least 16°C as the lower value so that the temperature does not fall below the dew point. Taking into account a safety buffer, a flow temperature of 17-18°C should be set for cooling at the chiller or heat pump.

Cooling capacity in [W/m²] |

||||||

Average cooling water temperature* |

19°C |

18°C |

17°C |

|||

Room temperature |

25°C |

27°C |

25°C |

27°C |

25°C |

27°C |

Cooling capacity in W/m2 |

19,1 |

25,8 |

22,4 |

29,1 |

25,8 |

32,5 |

*for the FLEXIRO chilled ceiling, a ∆T of 2K between supply and return is recommended.

Unfortunately, it is not possible to control the room temperature in cooling mode with the RTL valves offered. The RTL boxes are designed for heating only. Mechanical thermostatic heads do not have a reverse function. Alternatively, the room temperature can be controlled in cooling mode by controlling the flow temperature. When the thermostatic head is set to the highest value, the valve is always open in summer, allowing cooling water to flow into the ceiling cooling system. If the room cools down too much, the flow temperature at the chiller or heat pump is increased until the room temperature is comfortable.

Other solutions for controlling a chilled ceiling are possible, but also costly. For the set sizes offered, the cost of additional control technology is only worthwhile for larger cooling surfaces.