This Is How It Works: Installing Underfloor Heating with Dry Screed Panels

Installation instructions

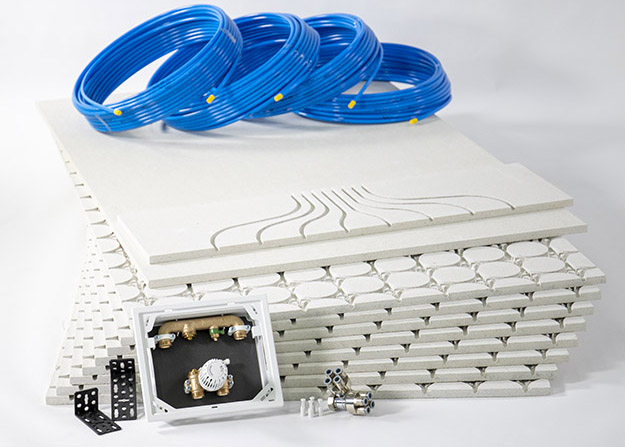

The underfloor heating with pre-fabricated dry screed panels is a system kit that has been put together for particularly easy, quick and clean installation. Installation is carried out in accordance with dry construction standards. The 10 mm PE-RT heating pipes for the underfloor heating are inserted into the pre-milled screed panels. Finally, the underfloor heating is integrated into the existing heating system using the RTL box supplied.

The installation of the drywall system is simplified by the use of special plug-in connectors for PE-RT pipes, making our underfloor heating kit suitable for DIY enthusiasts. The main installation steps are illustrated below using an example installation of approximately 6 m². The kits are supplied with detailed installation instructions.

DIY installation of underfloor heating in drywall construction

Scope of supply

The components of the underfloor heating kit vary according to the size of the kit and can be found in the PDF installation instructions and on the relevant product page. You can also find additional accessories and suitable tools in our shop.

Note

Despite the simplified installation, the following still applies to FLEXIRO thin layer underfloor heating: Work on heating systems requires sufficient technical knowledge and skills. If in doubt, have the installation carried out by a specialist.

1

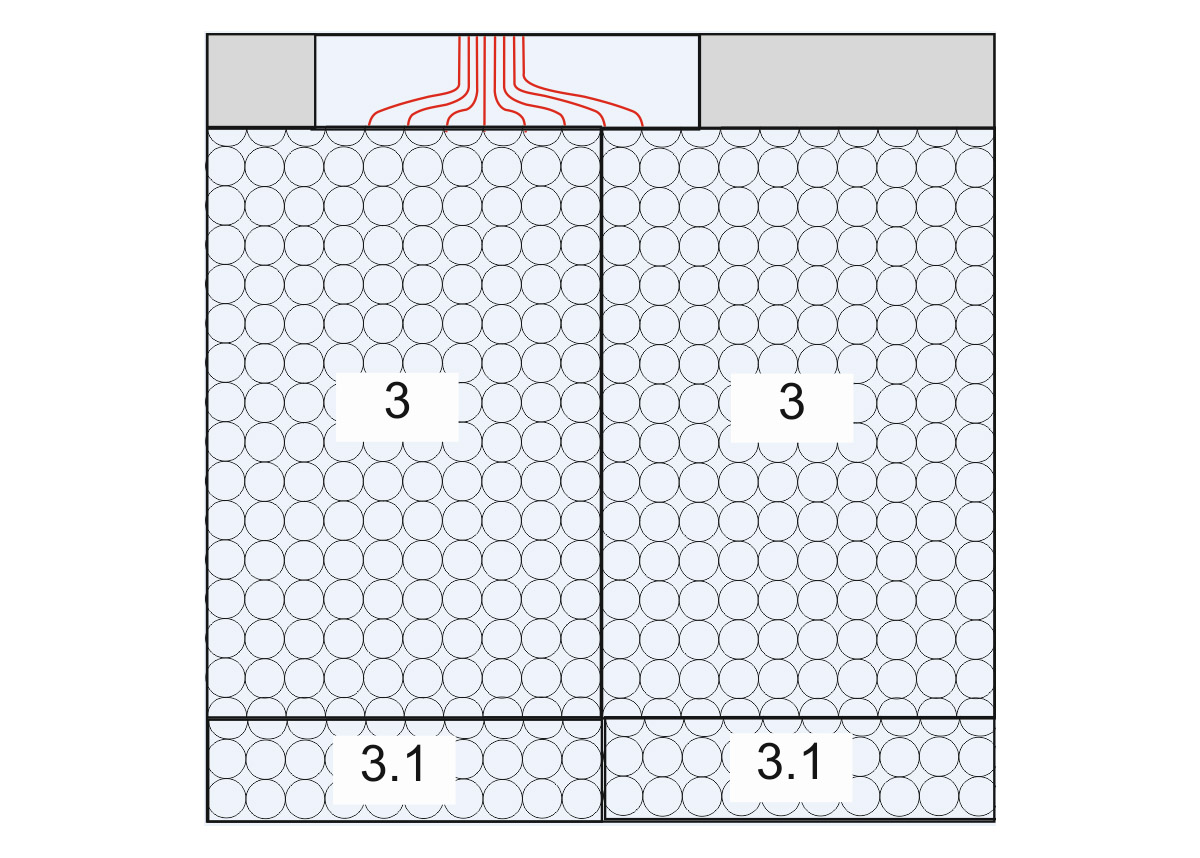

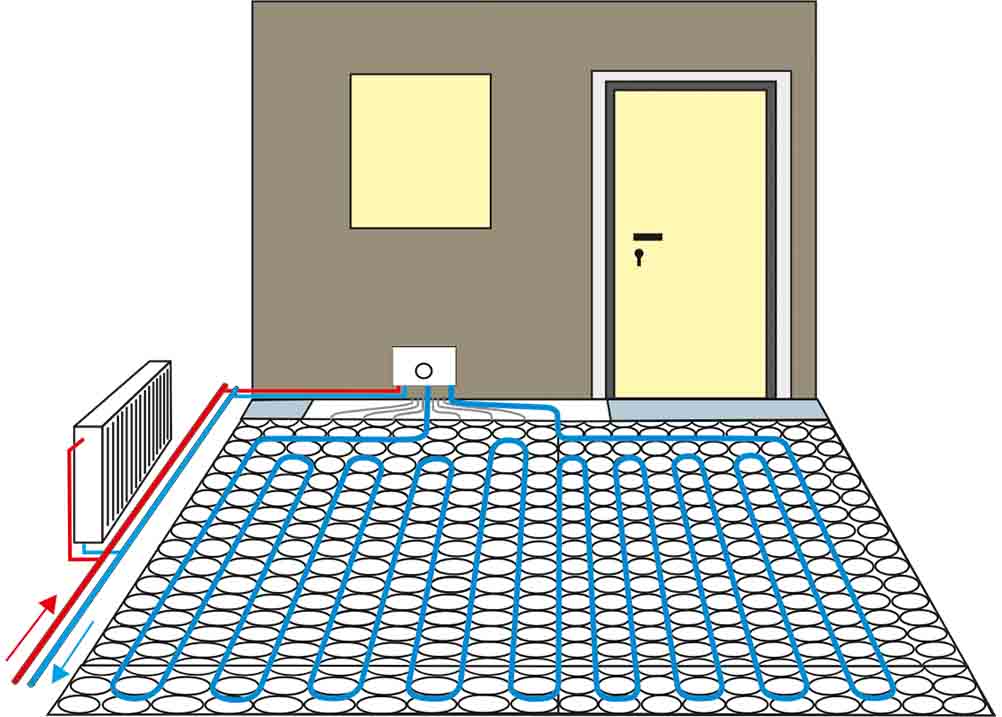

Arrangement of heating circuits and components

Determine the layout of the heating circuits. The location of the RTL box should be such that the heating pipes of all the circuits can be routed directly to the control box without extending the heating pipes.

Set 2.5 m² = 1 heating circuit; 5.0 m² = 2 heating circuits; Set 7.5 m² = 3 heating circuits and 10.0 m² = 4 heating circuits.

In principle, the underfloor heating pipes can be shortened. However, care must be taken to ensure that the difference in length between the individual connections is not too great (max. 15% difference in length).

Caution: The dry screed underfloor heating can be operated with a maximum system temperature of 54°C. Higher temperatures will cause long-term damage to the dry screed panels.

2

Positioning of the components

The existing substrate must be a level, clean, dry and load bearing plasterboard surface. The first step is to draw up a layout plan showing the position of the pre-milled drywall panels and the position of the RTL box. The heating pipes should be able to run from the RTL box to the heating surface and back without overlapping.

The RTL valve should remain accessible after installation. The distance from the floor should be at least 20 cm so that the pipe ends can still be inserted into the individual connections after the manifolds have been installed.

3

Mounting the RTL box

For accurate and efficient temperature control, the RTL box should be positioned so that the thermostatic head can measure the temperature of the room air and the air can flow freely around it.

Please refer to the RTL box installation and operating instructions supplied separately.

4

Installation of the edge insulation strip

The next step is to lay a strip of edge insulation, at least 20 mm wide, around the surface of the floor to be heated. Columns or similar should also be surrounded by the edge insulation strip to allow the entire floor structure to expand.

The edge insulation strip is cut off after the final floor covering has been laid (in the case of tiled floors, after grouting).

5

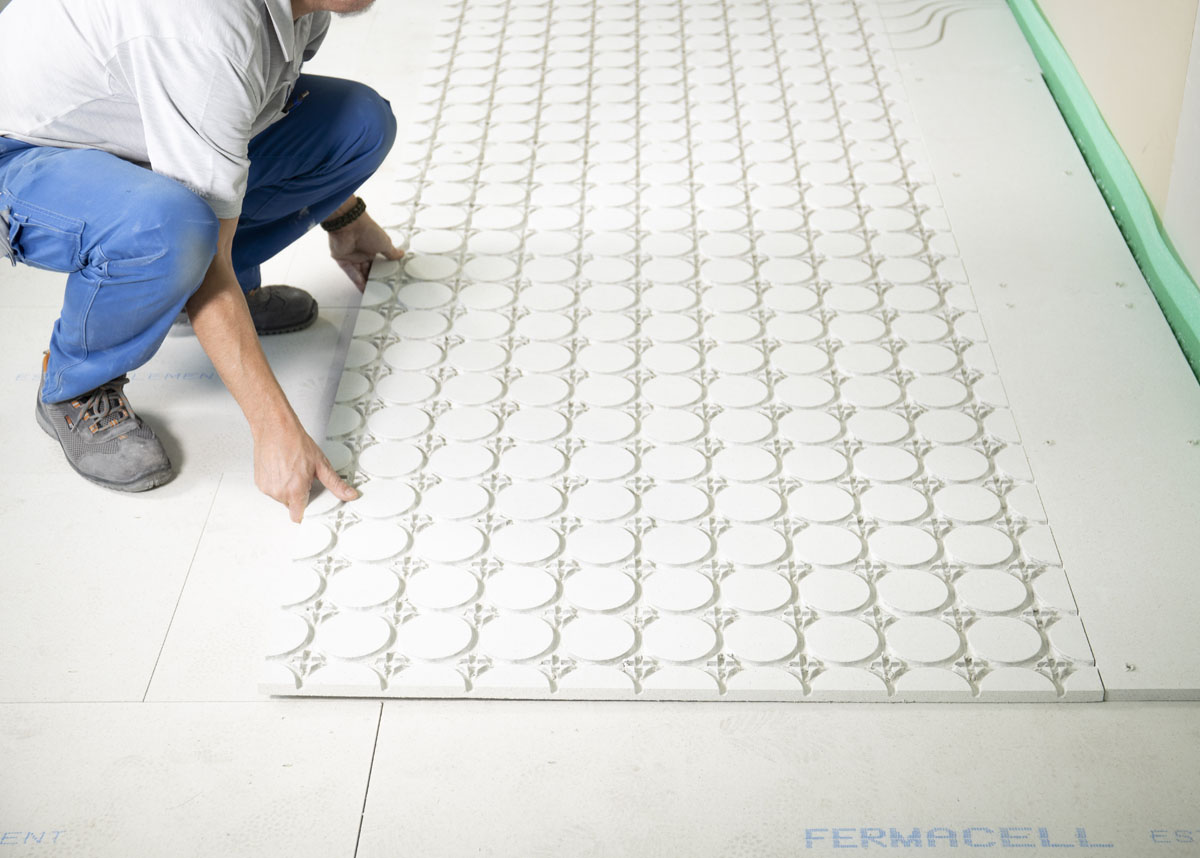

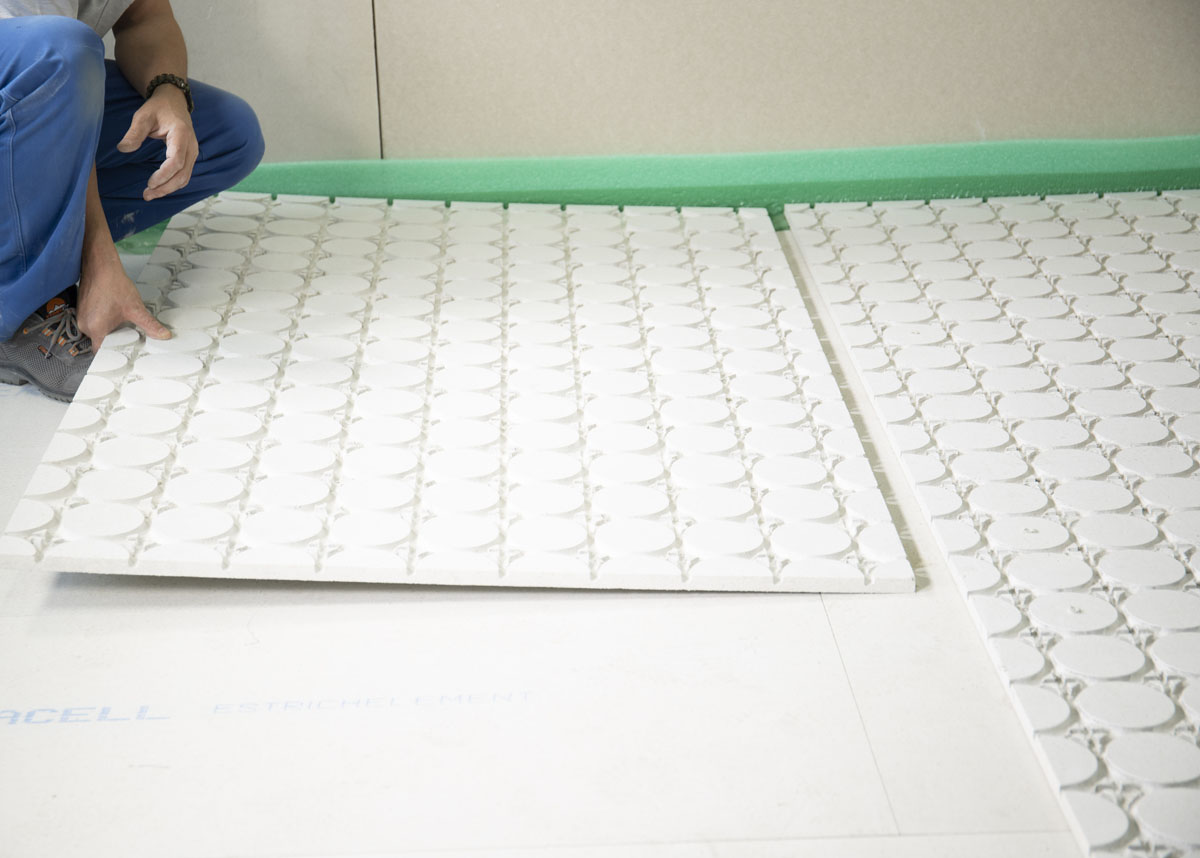

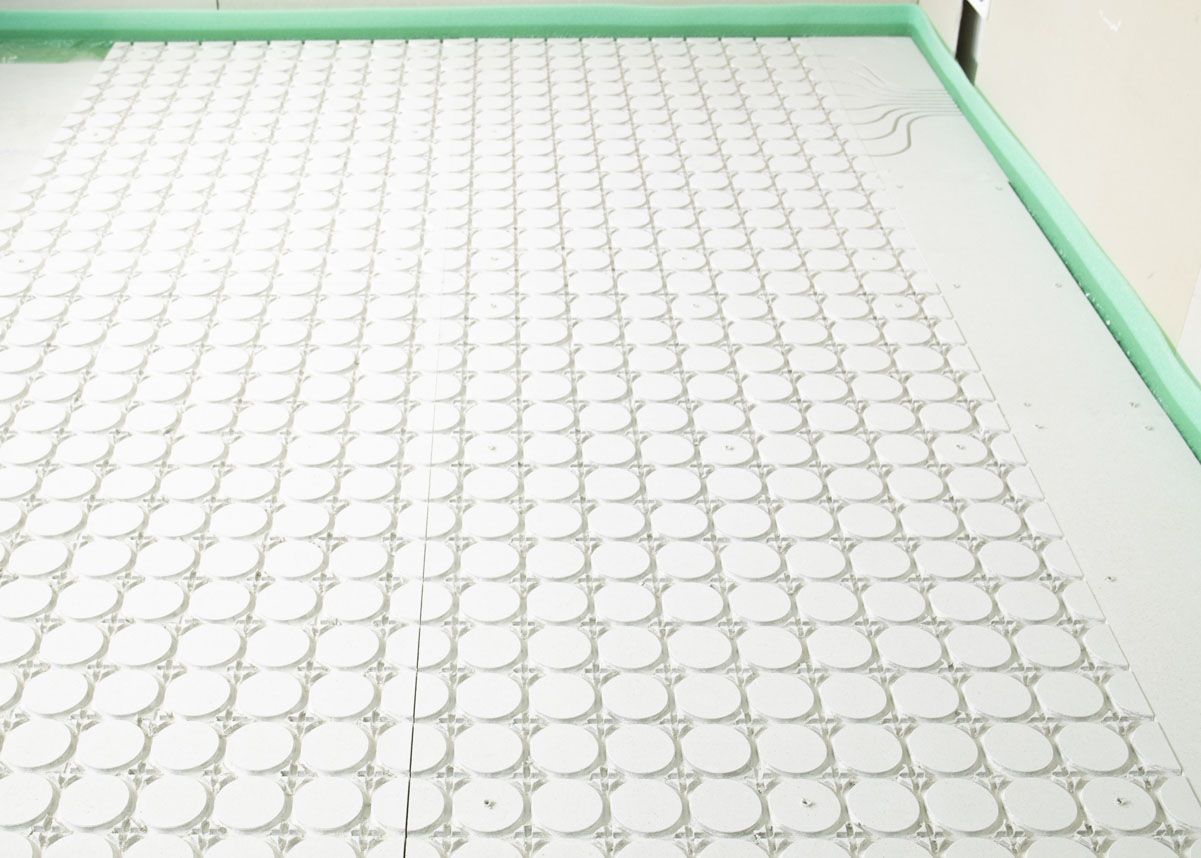

Laying screed boards

Prior to installation, transfer the planned heating area to the floor and cut the dry screed panels to size as required. Use a circular saw, jigsaw or handsaw with a suitable blade for cutting.

Caution: The pre-milled screed panels are only required for the intended heating area. Standard screed panels are used in the unheated edge areas and to completely fill the 3rd layer.

The pre-milled screed panels are glued to the existing finished screed with screed adhesive (PU adhesive) and additionally fastened with drywall screws or staples. The screed adhesive is applied to the floor only. It is not necessary to apply the adhesive over the entire surface. It is sufficient to apply adhesive cords. Detailed information on the gluing process is available from the board manufacturers.

The feed plate must be aligned so that the heating pipes can be routed to the RTL box.

6

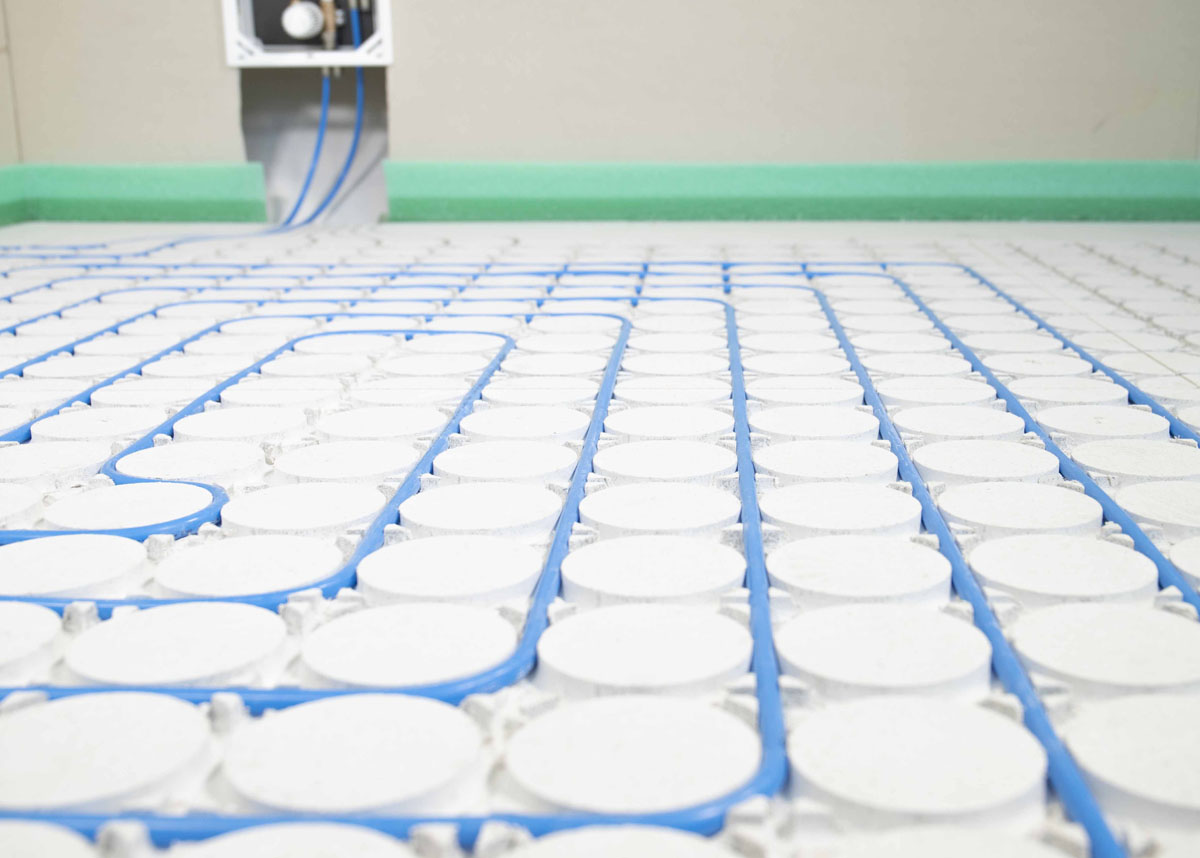

Laying the heating pipe

Ideally, the laying of the heating pipe should start close to the manifolds in order to minimise the length of pipe required for the connection. The minimum distance between the pipes is 10 cm. The distance between the underfloor heating and the walls of the room should be at least 5 cm.

The pipes must be laid without twisting. If dry screed panels are used, a spiral installation is recommended. In addition to very even heat distribution, it also has large radii that allow for a twist-free installation. Care should be taken when walking on the dry screed boards. Before filling the grooves with suitable joint filler, ensure that the heating pipe is fully secured and does not protrude from the grooves.

In case of damage to the heating pipe

The heating pipe should always be cut straight and burr-free. It must not be crushed or kinked. Kinked or damaged sections of the heating pipe must be cut out. The pipe must be reconnected using a permanently tight coupling. The coupling must be protected from direct contact with the casting compound by wrapping it in PE film. Mark the position of the coupling. After this repair the pipes may need to be extended.

7

Underfloor heating installation layouts with dry screed panels

Several installation layouts are available and can be adapted to suit the space available. However, spiral installation is more suitable for use with dry screed boards due to less tight bending radii. The use of additional fixings is recommended when using a meandering installation. Pipe crossings should be avoided at all costs when planning the installation in order to take full advantage of the low installation height of thin layer underfloor heating.

8

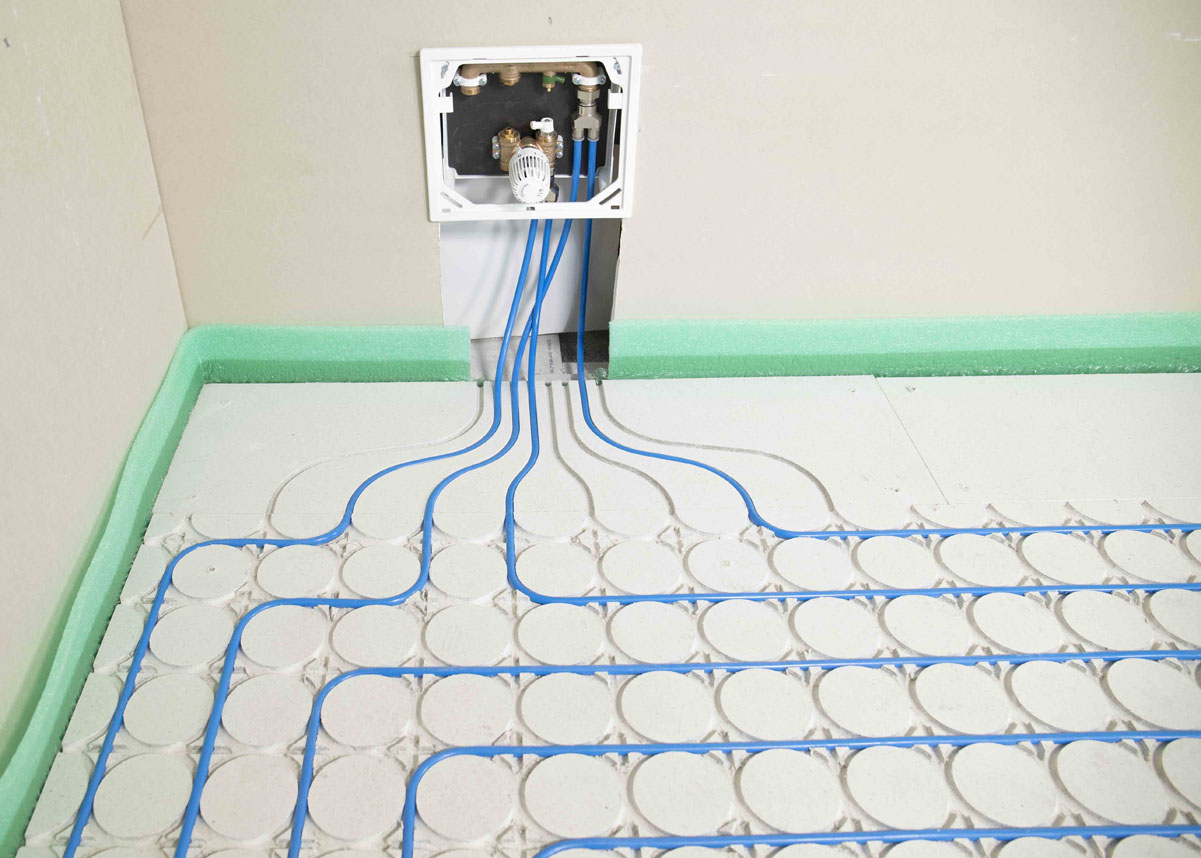

Connecting the RTL Box

The manifold fingers are connected to the RTL box with a Eurocone screw joint. The Eurocone has a self-sealing effect, while the metal screw connection has a purely locking function. Over-tightening must be avoided at all costs in order not to compromise the tightness of the heating system.

The heating pipes in the manifolds are connected using a simple plug-in system. The heating pipes, which are cut straight and shortened if necessary, are inserted directly into the plug-in connections of the manifold fingers as far as they will go.

9

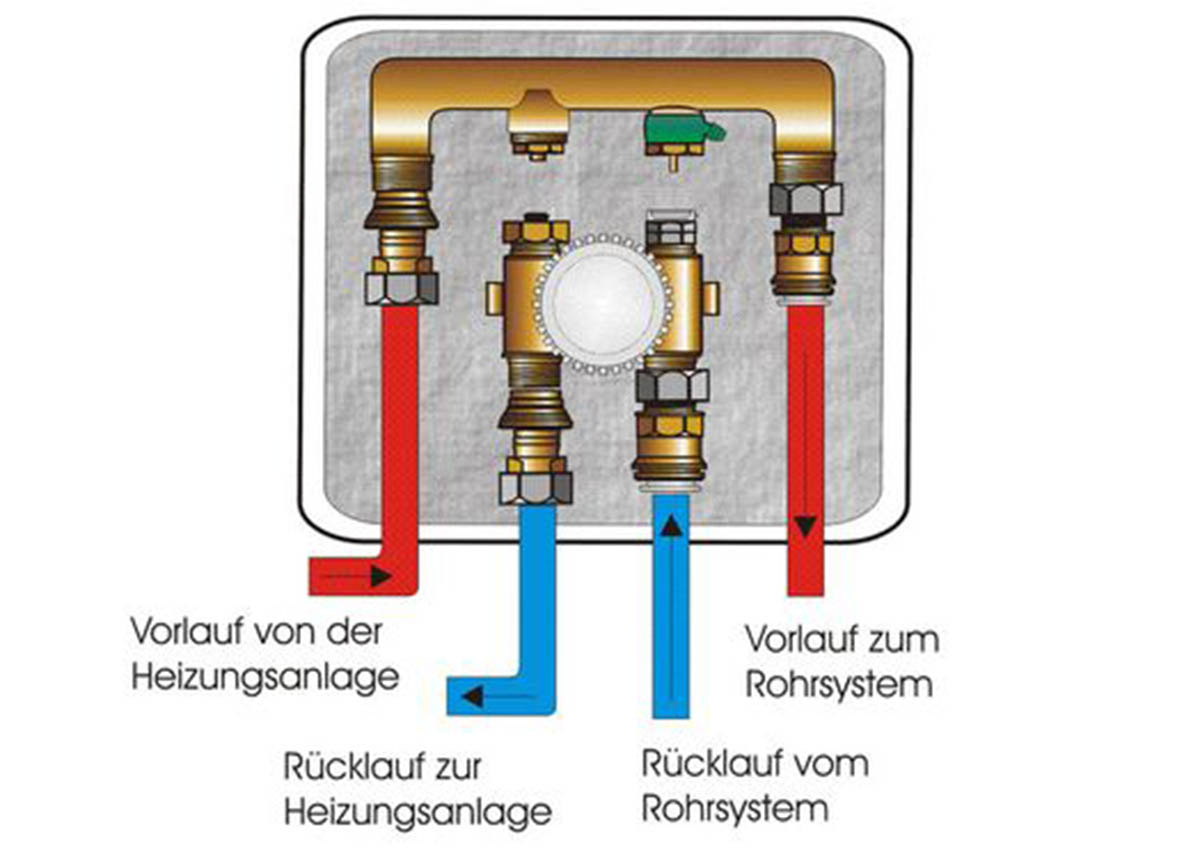

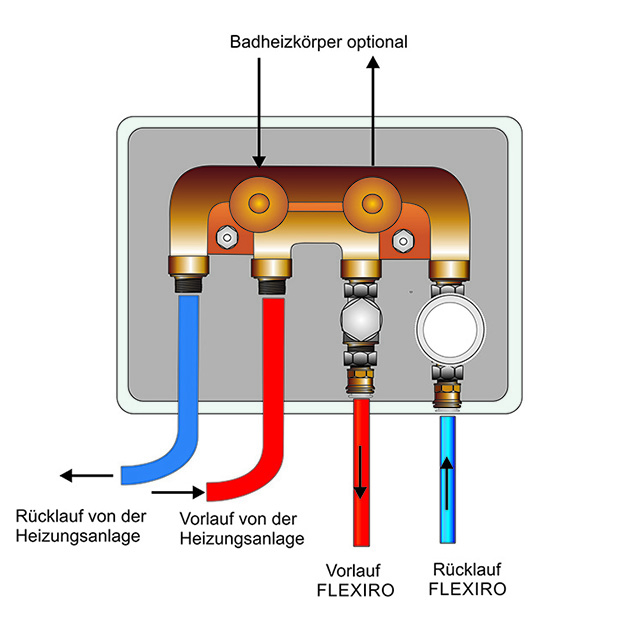

Connecting the heating system

The FLEXIRO underfloor heating is normally integrated into the existing heating system in parallel with other radiators or as a replacement for an old radiator. Both is possible. This is done by inserting a T-piece (not supplied) into the flow and return pipes of the heating system.

Make sure that the flow and return are correctly assigned in the RTL box. Reversing the flow and return in the control box will disable the thermostatic valve and prevent the underfloor heating from operating.

10

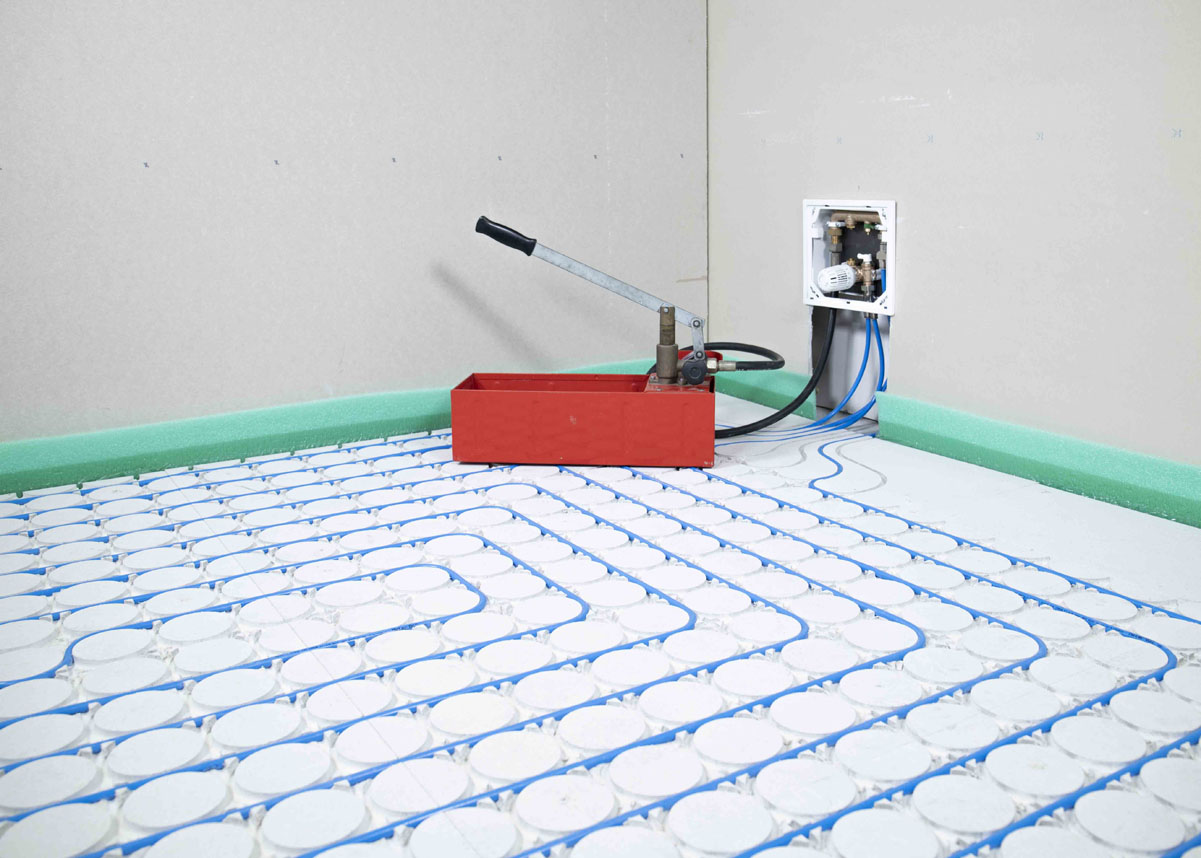

Carrying out a pressure test

Before commissioning the underfloor heating system, it is essential to ensure that the system and all associated components are correctly installed and tight. For this, a pressure test pump is available as an accessory in the shop.

See video for exact procedure and connections for pressure test

11Test run of the underfloor heating

We strongly recommend carrying out a test run of the underfloor heating before covering the pipe system with levelling compound. This is the last opportunity to correct any installation errors or damage!

12

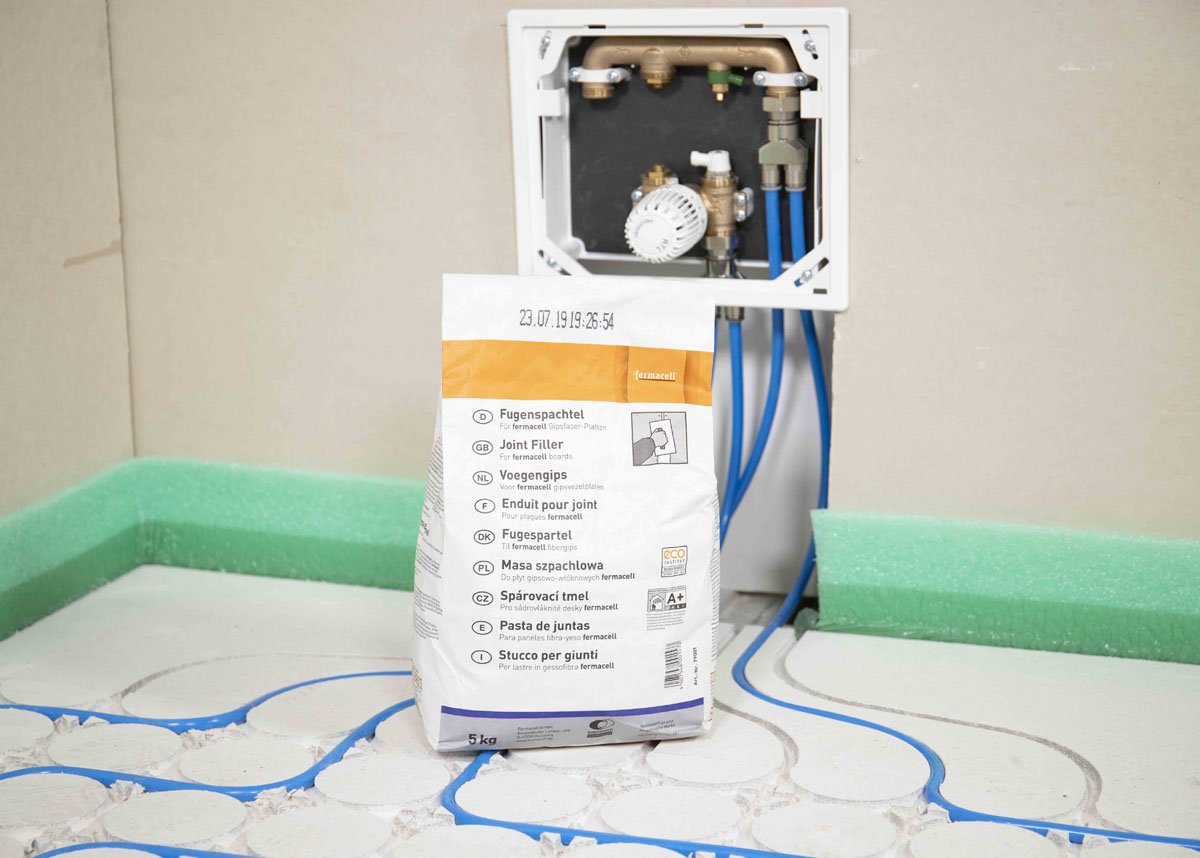

Applying the levelling compound

A levelling compound or alternatively a gypsum based levelling compound should be used to fill the grooves in the screed boards in accordance with the manufacturer's instructions.

When selecting a suitable construction compound (levelling compound) for underfloor heating, it is important to ensure that it is marked as "flexible". The underfloor heating must be switched off when applying the levelling compound! The minimum construction height is 12 mm if a ceramic covering is chosen. For other surface coverings, the levelling compound should have an additional cover of at least 5 mm of the heating pipe. All coverings must be marked "suitable for underfloor heating".

Fill all unused grooves in the screed panels with the joint filler.

Top covering

Ceramic or stoneware tiles in the 330x330 mm format can be laid without difficulty. The suitability of larger formats should be checked with the tile manufacturer in relation to the floor construction. Please pay attention to the need to comply with laws, regulations, guidelines and standards when designing and installing heating systems and when carrying out dry construction work.

13Commissioning of the underfloor heating

Once the surface covering has been completed and allowed to dry naturally, the heating process can begin. If the floor is to be tiled, the underfloor heating should not be switched on until the tile adhesive is fully hardened. Heating is usually carried out according to a heating protocol. Follow the manufacturer's instructions for the construction chemicals used.

14At last

Despite the simple design of the underfloor heating system and the ease of installation, we must point out that, as the manufacturer, we can only guarantee correct delivery from the factory and not installation and connection by third parties. Please also observe the current standards and regulations for heating systems.

FLEXIRO wishes you every success!

19-

Installation Guide - How to Install Drywall Underfloor Heating KitsComprehensive installation guidelines with all required information for retrofitting a FLEXIRO underfloor heating with ready-to-build dry screed boards.832 KB

Installation Guide - How to Install Drywall Underfloor Heating KitsComprehensive installation guidelines with all required information for retrofitting a FLEXIRO underfloor heating with ready-to-build dry screed boards.832 KB

help

The Bostik company says yes! However, floating timber structures are not permitted as they are highly susceptible to deformation. Installation is therefore only possible on fixed timber structures, whereby these must be uncoupled. Please contact us for further information on laying on fixed timber structures!

The existing substrate must always be level, clean, dry and load-bearing.

FLEXIRO underfloor heating can be installed on OSB boards. Bostik's instructions clearly state that the OSB boards must be bonded to the substrate. Floating OSB boards are not suitable. The OSB boards must be primed before laying the FLEXIRO underfloor heating. In this case, the pipes should be covered with at least 5 mm of screed.

Due to the installation of the low profile underfloor heating directly below the surface, additional insulation is not required in most cases. This keeps the installation height low. Exceptions are floors above unheated basements and the ground. The requirements of the Energy Saving Ordinance must be observed. Further information on thermal insulation for underfloor heating

The low profile underfloor heating is designed for mounting directly on the existing surface. The modernisation of an existing and already insulated floor usually does not require additional insulation of the underfloor heating. Therefore we only sell special insulation boards for bathrooms and other wet areas. Additional floor insulation can be bought at any specialist store. Once the insulation has been applied, you need to ensure a stable surface before installing the underfloor heating.